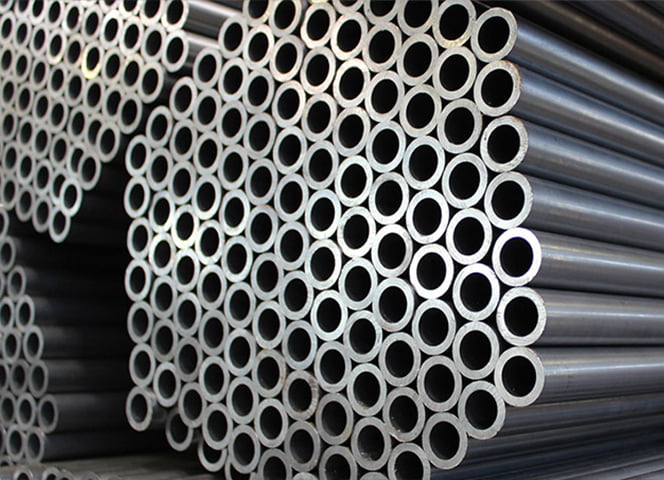

Cold-drawn Precision Seamless Steel Tube

Introduction:

Cold-drawn precision seamless steel tube is made through cold drawing process that creates a uniform, precision product with substantially improved tolerances, surface finish and tensile strength, increased hardness, and good machinability. Close dimensional accuracy is achieved through tight control of both outside and inside diameters.

Compared with hot rolled seamless steel tube, cold drawn seamless steel tube features higher strength, better extensibility, and higher abrasion resistance. It can be used for automobile shock absorber, drive shaft, steering system, airbag system, motorcycle front fork and so on.

Standard

- GB/T8713《Precision ID seamless tubes for hydropneumatic purposes》

- GB/T3639《Cold-rolled and cold drawn precision seamless steel tubes》

- EN10305-1《Seamless cold drawn tubes》

- EN10305-4 《Seamless cold drawn tubes for hydraulic and pneumatic power systems》

- DIN2391《Seamless precision steel tubes》

- JIS-G3445《Carbon steel tubes for machine structural purpose》

- ASTM-A519 《Seamless carbon and alloy steel mechanical tubes》

- AMS-T-6736A《Tubing, Chrome-Molybdenum (4130 or 8630) steel, seamless and welded》

- SAE J524《Seamless low-carbon steel tubing annealed for bending and flaring》

- GOST8734-75 《Seamless cold deformed steel tubes》

- BS6323《Seamless and welded steel tubes for automobiles, mechanical and general engineering purpose》

Application Accessories Display

Cold-drawn precision seamless tubes can be applied in the following aspects:

- Automobile shock absorber cylinder

- Steering system

- Drive shaft

- Aigbag inflator

- Seat belt tensioner

- Motorcycle front fork

- Motorcycle framework

- Other precision application

Production Facility

Pretreatment

Acid Pickling

Cold Drawn

Package and Storage

Pipe Cutting