In the intricate world of automotive engineering, precision is paramount. Every component, no matter how small, plays a crucial role in ensuring the vehicle’s overall performance, safety, and efficiency. One such component that often goes unnoticed but holds immense significance is precision tubes.

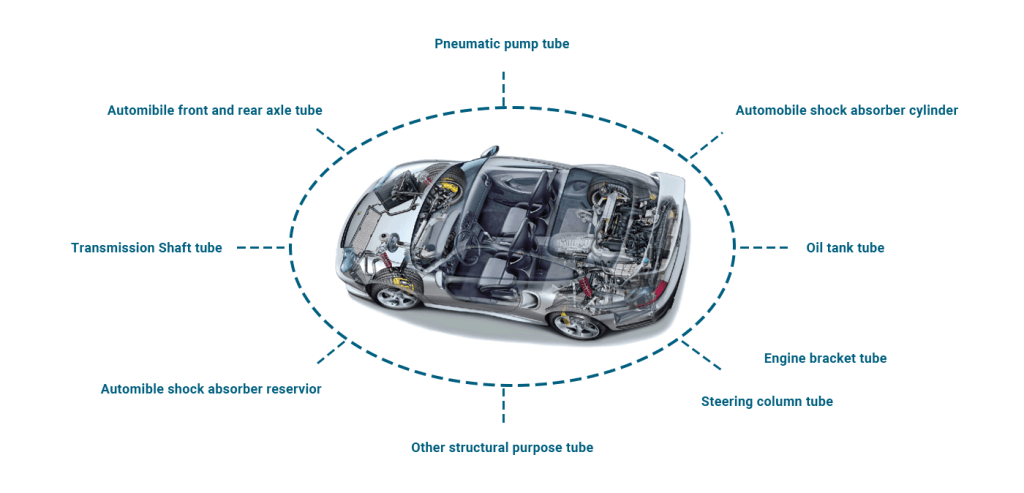

Precision tubes, also known as seamless tubes, are cylindrical tubes manufactured with high accuracy and tight tolerances. These tubes find widespread application across various industries, with the automotive sector being one of the primary beneficiaries. Let’s delve into how precision tubes contribute to enhancing automotive performance:

Strength and Durability: Automotive components, especially those exposed to high levels of stress and pressure, require exceptional strength and durability. Precision tubes, manufactured using advanced techniques such as cold drawing or hot extrusion, offer superior mechanical properties compared to conventional welded tubes. This enhanced strength ensures that critical automotive systems like chassis, suspension, and exhaust remain robust and reliable under demanding conditions.

Weight Reduction: In the pursuit of fuel efficiency and environmental sustainability, automotive manufacturers are constantly seeking ways to reduce vehicle weight without compromising structural integrity. Precision tubes, characterized by their thin walls and uniform dimensions, contribute significantly to weight reduction efforts. By replacing heavier components with lightweight precision tubes, automakers can achieve substantial fuel savings while improving overall vehicle performance and handling.

Optimized Fluid Dynamics: Fluid-carrying systems, such as fuel lines, brake lines, and hydraulic systems, rely on precision tubes to maintain optimal fluid dynamics. The seamless construction of precision tubes minimizes internal turbulence, pressure drops, and flow restrictions, ensuring efficient fluid transfer throughout the vehicle. This not only enhances the responsiveness of critical automotive systems but also contributes to improved fuel economy and brake performance.

Customization and Flexibility: Autootive design is constantly evolving to meet changing consumer preferences, regulatory requirements, and technological advancements. Precision tubes offer unparalleled customization and flexibility, allowing engineers to design complex shapes and configurations tailored to specific application needs. Whether it’s a custom exhaust system for a high-performance sports car or a lightweight frame for an electric vehicle, precision tubes empower automotive manufacturers to push the boundaries of innovation and design.

Corrosion Resistance: Exposed to harsh environmental conditions and corrosive substances, automotive components must withstand corrosion to ensure long-term reliability. Precision tubes, often made from corrosion-resistant alloys such as stainless steel or aluminum, offer superior protection against rust, oxidation, and chemical degradation. This extends the lifespan of critical automotive systems, reducing maintenance costs and enhancing overall vehicle longevity.

In conclusion, precision tubes play a pivotal role in enhancing automotive performance across various fronts, including strength, weight reduction, fluid dynamics, customization, and corrosion resistance. As automotive technology continues to advance, the demand for precision-engineered components like seamless tubes will only continue to grow, driving innovation and efficiency in the automotive industry.